The Rise of Tire Recycling Downstream Products: From Waste to Worth

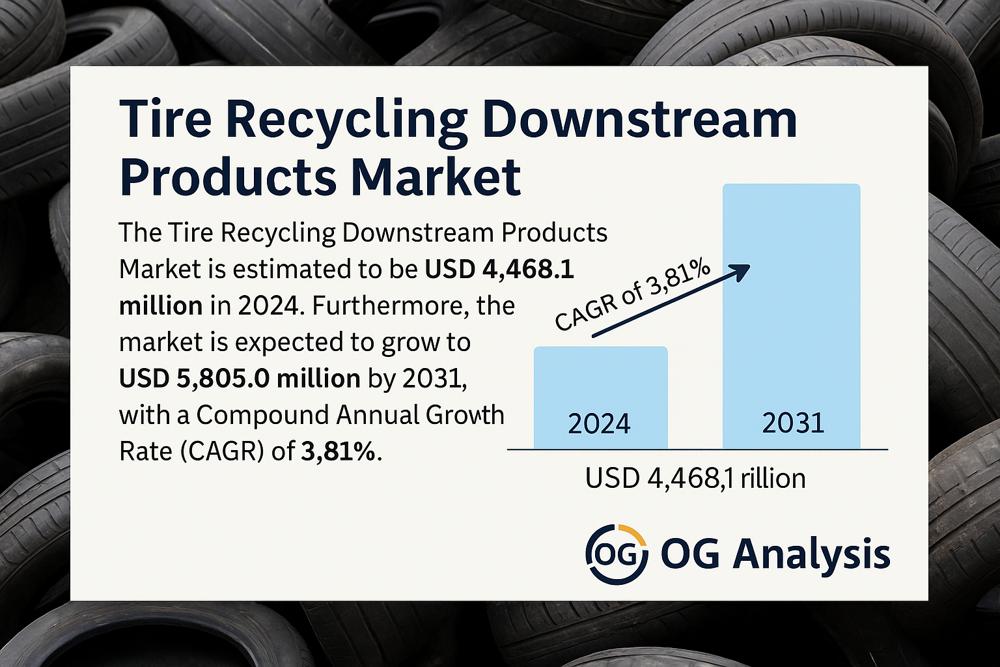

With sustainability becoming a global imperative, the Tire Recycling Downstream Products Market is carving out a powerful niche within the circular economy. Valued at USD 4,468.1 million in 2024, the market is projected to grow to USD 5,805.0 million by 2031, driven by a steady CAGR of 3.81%. As industries pivot toward eco-efficient materials and energy sources, the value chain of recycled tire products is gaining major traction.

From crumb rubber and tire-derived fuel to steel recovery and rubber mulch, downstream innovation is transforming used tires into high-performance, low-impact solutions across multiple sectors—including construction, energy, playgrounds, and manufacturing.

1. Why is tire recycling gaining momentum in the era of green manufacturing?

Tire recycling has shifted from an environmental necessity to an economic opportunity. As governments roll out stricter landfill regulations and carbon-neutral goals, industries are turning to recycled materials for infrastructure and fuel. Downstream products like tire-derived aggregates and fuel are being widely adopted due to their cost-effectiveness, durability, and reduced environmental footprint—especially in cement kilns and construction fillers.

2. Pyrolysis vs. Shredding: Which recycling technique is shaping the future?

Both are game-changers—but serve different purposes. Shredding remains the most widely used method, ideal for producing crumb rubber, mulch, and aggregates. However, pyrolysis is gaining popularity due to its ability to produce oil, gas, and recovered carbon black—adding value to energy and chemical markets. Companies are investing in closed-loop pyrolysis systems that reduce emissions and increase yield, making it a technology to watch in the next phase of market evolution.

3. How are recycled tire products influencing modern infrastructure?

Construction and infrastructure sectors are increasingly incorporating tire-derived aggregates (TDA) and crumb rubber into roadbeds, drainage systems, and insulation layers. These materials offer shock absorption, drainage efficiency, and resistance to compression, making them ideal for large-scale civil works. With infrastructure spending surging globally, especially in emerging markets, recycled tire inputs are aligning with both economic and ESG goals.

Click Here for the Full Market Report

4. Is there a playfield revolution happening with rubber mulch and infill?

Absolutely. Sports surfaces, school playgrounds, and recreational fields are adopting rubber mulch and fiber due to their shock-absorbing properties, safety standards compliance, and long-term durability. Cities and schools are also choosing tire-derived products for their non-toxicity, low maintenance costs, and rainwater permeability. This segment continues to expand as public awareness around child safety and eco-friendly infrastructure grows.

5. How is tire-derived fuel reshaping the energy supply chain for heavy industries?

Tire-derived fuel (TDF) is making waves as a low-cost, high-energy alternative to fossil fuels, especially in cement manufacturing, pulp and paper mills, and utility boilers. Its high calorific value and lower emissions profile make it a compelling choice. As energy prices rise and regulatory pressure intensifies, TDF is becoming a reliable part of the industrial fuel mix, particularly in Asia-Pacific and Europe.

6. Can recovered steel and fiber become key players in material circularity?

Yes. The steel extracted from tires during the recycling process is finding its way into metal smelting, rebar production, and even automotive components. Meanwhile, fiber remnants are being tested in composite materials and soundproofing applications. As manufacturers explore ways to reduce raw material dependence, these secondary outputs are becoming sought-after circular resources.

7. Which regions are spearheading innovation and adoption in tire recycling?

North America and Europe are leading due to strong regulatory frameworks and robust recycling infrastructures. However, Asia-Pacific, particularly China and India, is experiencing rapid growth thanks to increasing tire waste volumes and supportive government incentives. Latin America and Africa are emerging players, focusing on decentralized recycling units and low-cost pyrolysis plants to meet growing environmental mandates and employment goals.

Click Here for the Full Market Report

Market Segmentation Overview

By Recycling Technique:

-

Pyrolysis

-

Shredding

By Product:

-

Crumb Rubber & Fiber

-

Rubber Mulch

-

Tire-derived Fuel

-

Tire-derived Aggregates

-

Steel

-

Others

By End Use:

-

Cement Manufacturing

-

Construction & Infrastructure

-

Sports Surfaces and Playgrounds

-

Tires & Rubber

-

Pulp & Paper Mills

-

Utility Boilers

-

Others

By Geography

-

North America (USA, Canada, Mexico)

-

Europe (Germany, UK, France, Spain, Italy, Rest of Europe)

-

Asia-Pacific (China, India, Japan, Australia, Rest of APAC)

-

The Middle East and Africa (Middle East, Africa)

-

South and Central America (Brazil, Argentina, Rest of SCA)

Explore More Industry Insights

|

Motorized Quadricycle Market Outlook Report

|

| Global Motorcycle Rider Accessories Market Outlook |

Connect with us on:

Phone: +91 888 64 99099

Email: mailto:sales@oganalysis.com

Learn More about OG Analysis

OG Analysis, established in 2009 has 14+ years of experience and served 1800+ clients from 980+ companies operating in 54+ countries. OG Analysis is a leading provider of market research reports in Chemicals, Energy, Oil & Gas, Food & Beverage, Electronics & Semiconductors, Automotive, Telecommunication, Healthcare and Other industries.