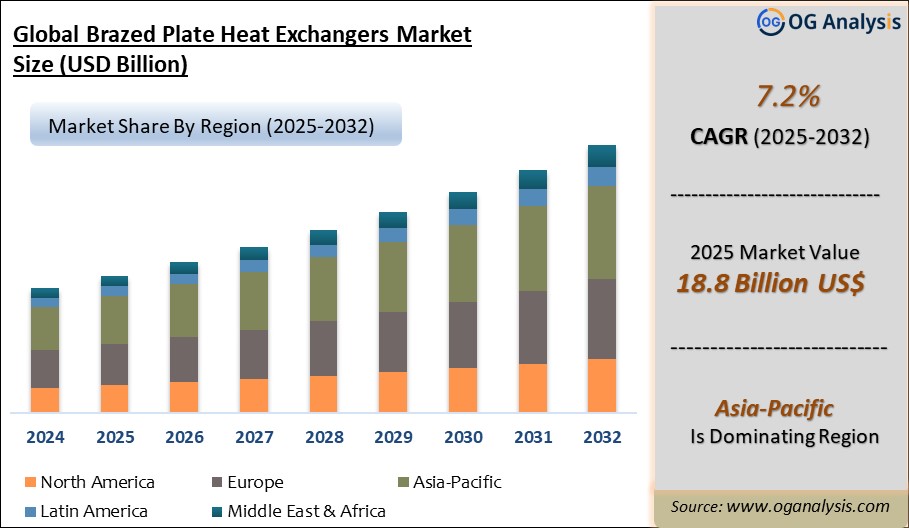

The Brazed Plate Heat Exchangers Market is estimated at USD 15.3 billion in 2022. Further, the market is expected to grow from USD 16.03 billion in 2023 to USD 23.02 billion in 2030 at a CAGR of 7.2%.

Brazed Plate Heat Exchangers Market Market Overview

A Brazed Plate Heat exchanger system is engineered to stop a fire from growing and spreading. With the use of Brazed Plate Heat exchanger systems, fires can be extinguished, kept under control, or avoided. Either heat, smoke, or a combination generally activates the suppression systems. Many Brazed Plate Heat Exchanger systems come with fire detection mechanisms and signaling systems that alert occupants to the problem and direct them to take further suppression action.

The benefits of Brazed Plate Heat Exchanger systems include improved site & personal safety, safe & ease to use, early fire detection, fast & effective, and suitable for most sites. The common Brazed Plate Heat Exchanger types include gas-based, water-based, and wet and dry chemical suppression. Water, foam, CO2, steam, inert gases, and dry chemical powders are fire control agents or media. Inert gases such as nitrogen and aragonite are useful fire suppressants.

Asia-Pacific is the leading region in the brazed plate heat exchangers market, powered by stringent energy efficiency regulations, widespread adoption of renewable heating systems, and strong demand from the HVAC and industrial sectors. The HVAC segment is the top segment in the market, fueled by rising urbanization, increasing commercial infrastructure, and the growing focus on compact and efficient thermal management solutions.

Brazed Plate Heat Exchangers Market Latest Trends ,Driving and Challenges

Technological advancements in Brazed Plate Heat Exchanger systems:

One of the most in-demand Brazed Plate Heat Exchangers systems is the FM200 Brazed Plate Heat Exchangers system, which uses no water to provide fire protection. Globally, modern trends and developments in fire-detection & suppression systems are based on three segments: sensors, signage, and communication. In the field of sensors, the most notable development has been the addition of combined visible smoke and carbon monoxide (CO) sensors to the NFPA code.

In recent years, the most significant trend in signage has been integrating voice evacuation systems with fire detection systems. Another factor that determines the development of fire-detection systems is legislation in the form of standards and certifications. The other advancements include IoT in Fire Safety Systems & connected detectors: The IoT has resulted in much of the world evolving smarter & more connected. With IoT, now safety alerts can be sent to many people quickly & effectively. Many leading organizations are rendering connected smoke detectors for residential use because they can communicate with the Thermostat, which can close the furnace during a fire.

Mass Notification System: Most facility owners & managers are coming to know the benefits of integrating all the building systems, including mass notification and security systems. Wireless Technology: At present, wireless smoke detectors come in more compact and streamlined designs, which can be more appealing. Voice Alert Systems: Systems announcing danger with pre-recorded messages continue to gain traction and, at present, will keep their demand high soon. Machine Learning: The fastest-growing application for ML in the building segment is for improving maintenance. While Machine Learning technologies are implemented for swift maintenance of fire alarm systems, Machine learning applications are highly automated, embedded & self-modifying.

Strict government regulations for the adoption of Brazed Plate Heat Exchangers systems:

Government authorities across the globe have been taking new initiatives and launching directives regarding implementing Brazed Plate Heat Exchangers systems & protection systems at offices and buildings along with buses. Developing countries' governments are expanding the categories of buildings that need a Brazed Plate Heat Exchanger system. With more and more buildings coming under the categories that need mandatory fire protection, there is an increase in demand for modern fire sprinkler systems.

A global coalition of over 80 fire-safety leadership organizations has launched a new Decade of Action for Fire Safety 2022-2032 to ensure an internationally consistent approach to the safety and management of buildings, infrastructure, and more to save lives by reducing risk and preventing devastating fires. Also, in India, the Ministry of Road Transport and Highways began the installation of fire alarms, fire protection systems, and suppression systems in school and passenger buses.

In 2021, in the U.S., nearly 1.3 million fire incidences were reported and caused over 3000 deaths. Due to this, NFPA has enacted guidelines for commercial business infrastructures to implement Brazed Plate Heat exchanger systems such as sprinklers and clean agent suppression systems.

High installation & maintenance costs of Brazed Plate Heat exchanger systems:

A high initial investment is required for the deployment of Brazed Plate Heat exchanger systems. According to NFPA, the average fire sprinkler installation costs around $1.35 per square foot of protected space. In general, larger suppression systems require more points of delivery, sensors, alarms, pull stations, piping, and other complicated control units. For example, a simple water sprinkler system installation in new construction can cost around $1 to $2 per square foot.

An annual inspection of a Brazed Plate Heat Exchangers system with fewer than 30 detectors will cost around $880 to $1,000. Larger suppression systems take longer to inspect and require more skilled technicians, costing around $1,800 to $4,000. The high costs are due to the complexity of networks and the need to develop sophisticated tools to counter a fire situation. Due to this, solution vendors need to upgrade their solutions and develop new technologies constantly.In addition to establishing general codes and safety standards, the NFPA also mandated the installation of fire protection systems in new commercial construction projects. In older buildings, they mandated the replacement of obsolete fire alarms, sprinklers, and detectors. As older properties update fire safety systems to adhere to new policies, remodeling activities are expected.

Companies Mentioned

Johnson Controls

Halma PLC.

Hochiki Corp.

Honeywell International Inc

Siemens AG

Robert Bosch GmbH

Firefly AB

Market Scope

|

Parameter |

Detail |

|

Base Year |

2024 |

|

Estimated Year |

2025 |

|

Forecast Period |

2026-2032 |

|

Market Size-Units |

USD billion |

|

Market Splits Covered |

By Product Type, By Application, By End User |

|

Countries Covered |

North America (USA, Canada, Mexico) |

|

Analysis Covered |

Latest Trends, Driving Factors, Challenges, Trade Analysis, Price Analysis, Supply-Chain Analysis, Competitive Landscape, Company Strategies |

|

Customization |

10% free customization (up to 10 analyst hours) to modify segments, geographies, and companies analyzed |

|

Post-Sale Support |

4 analyst hours, available up to 4 weeks |

|

Delivery Format |

The Latest Updated PDF and Excel Data file |

Market Segmentation

|

Market Split |

Detail |

|

By Product Type |

|

|

By End User |

|

|

By Application |

|

|

By Geography |

|

TABLE OF CONTENTS

1. GLOBAL BRAZED PLATE HEAT EXCHANGERS INDUSTRY

1.1. Market Scope and Definition

1.2. Study Assumptions

2. BRAZED PLATE HEAT EXCHANGERS MARKET LATEST TRENDS, DRIVERS AND CHALLENGES, 2021-2030

2.1. Brazed Plate Heat Exchangers Market Latest Trends

2.1.1. Technological advancements in Brazed Plate Heat Exchangers systems:

2.1.2. Increasing demand for water-mist Brazed Plate Heat Exchangers technology:

2.1.3. Rising deployment of Automated Fire Detection Systems:

2.1.4. Innovative product launches:

2.2. Brazed Plate Heat Exchangers Market Insights, 2022-2030

2.2.1. Leading Brazed Plate Heat Exchangers, by Product Type, 2022-2030

2.2.2. Leading Brazed Plate Heat Exchangers, by End User, 2022-2030

2.2.3. Dominant Brazed Plate Heat Exchangers Application, 2022-2030

2.2.4. Fast-Growing Geographies for Brazed Plate Heat Exchangers, 2021-2030

2.3. Brazed Plate Heat Exchangers Market Drivers to 2030

2.3.1. Strict government regulations for the adoption of Brazed Plate Heat Exchangers systems:

2.3.2. An increasing number of fire-related accidents:

2.3.3. Increased construction activity in residential & non-residential areas:

2.3.4. Use of eco-friendly extinguishing agents

2.3.5. Cost benefits of sprinkler systems

2.4. Brazed Plate Heat Exchangers Market Restraints to 2030

2.4.1. High installation & maintenance costs of Brazed Plate Heat Exchangers systems:

2.4.2. Technical Limitations:

2.4.3. Need for training in fire extinguisher usage

2.4.4. Increasing penetration of counterfeit fire extinguishers

2.5. Brazed Plate Heat Exchangers Market-Five Forces Analysis

3. GLOBAL BRAZED PLATE HEAT EXCHANGERS MARKET VALUE, MARKET SHARE, AND FORECAST TO 2030

3.1. Global Brazed Plate Heat Exchangers Market Overview, 2022

3.2. Global Brazed Plate Heat Exchangers Market Size and Share Outlook, By Product Type, 2021-2030

3.2.1. Single-circuit Brazed Plate Heat Exchangers

3.2.2. Multi-circuit Brazed Plate Heat Exchangers

3.3. Global Brazed Plate Heat Exchangers Market Size and Share Outlook, By End User, 2021-2030

3.3.1. HVAC-R

3.3.2. Chemical & Petrochemical

3.3.3. Power Generation

3.3.4. Food & Beverage

3.3.5. Heavy Industry

3.3.6. Other End-Users

3.4. Global Brazed Plate Heat Exchangers Market Size and Share Outlook, By Application, 2021-2030

3.4.1. Evaporator

3.4.2. Condenser

3.4.3. Economizer

3.5. Global Brazed Plate Heat Exchangers Market Size and Share Outlook by Region, 2021-2030

4. NORTH AMERICA BRAZED PLATE HEAT EXCHANGERS MARKET VALUE, MARKET SHARE, AND FORECAST TO 2030

4.1. North America Brazed Plate Heat Exchangers Market Overview, 2022

4.2. North America Brazed Plate Heat Exchangers Market Size and Share Outlook by Product, 2021-2030

4.3. North America Brazed Plate Heat Exchangers Market Size and Share Outlook, By End User, 2021-2030

4.4. North America Brazed Plate Heat Exchangers Market Size and Share Outlook, By Application, 2021-2030

4.5. North America Brazed Plate Heat Exchangers Market Size and Share Outlook by Country, 2021-2030

4.5.1. United States

4.5.2. Canada

4.5.3. Mexico

5. EUROPE BRAZED PLATE HEAT EXCHANGERS MARKET VALUE, MARKET SHARE, AND FORECAST TO 2030

5.1. Europe Brazed Plate Heat Exchangers Market Overview, 2022

5.2. Europe Brazed Plate Heat Exchangers Market Size and Share Outlook by Product Type, 2021-2030

5.3. Europe Brazed Plate Heat Exchangers Market Size and Share Outlook, By End User, 2021-2030

5.4. Europe Brazed Plate Heat Exchangers Market Size and Share Outlook, By Application, 2021-2030

5.5. Europe Brazed Plate Heat Exchangers Market Size and Share Outlook by Country, 2021-2030

5.5.1. Germany

5.5.2. France

5.5.3. UK

5.5.4. Italy

5.5.5. Spain

5.5.6. Rest of Europe

6. ASIA PACIFIC BRAZED PLATE HEAT EXCHANGERS MARKET VALUE, MARKET SHARE AND FORECAST TO 2030

6.1. Asia Pacific Brazed Plate Heat Exchangers Market Overview, 2022

6.2. Asia Pacific Brazed Plate Heat Exchangers Market Size and Share Outlook by Product Type, 2021-2030

6.3. Asia Pacific Brazed Plate Heat Exchangers Market Size and Share Outlook, By End User, 2021-2030

6.4. Asia Pacific Brazed Plate Heat Exchangers Market Size and Share Outlook, By Application, 2021-2030

6.5. Asia Pacific Brazed Plate Heat Exchangers Market Size and Share Outlook by Country, 2021-2030

6.5.1. China

6.5.2. Japan

6.5.3. India

6.5.4. South Korea

6.5.5. Rest of Asia Pacific

7. SOUTH AND CENTRAL AMERICA BRAZED PLATE HEAT EXCHANGERS MARKET VALUE, MARKET SHARE AND FORECAST TO 2030

7.1. South and Central America Brazed Plate Heat Exchangers Market Overview, 2022

7.2. South and Central America Brazed Plate Heat Exchangers Market Size and Share Outlook by Product Type, 2021-2030

7.3. South and Central America Brazed Plate Heat Exchangers Market Size and Share Outlook, By End User, 2021-2030

7.4. South and Central America Brazed Plate Heat Exchangers Market Size and Share Outlook, By Application, 2021-2030

7.5. South and Central America Brazed Plate Heat Exchangers Market Size and Share Outlook by Country, 2021-2030

7.5.1. Brazil

7.5.2. Argentina

7.5.3. Rest of South and Central America

8. MIDDLE EAST AFRICA BRAZED PLATE HEAT EXCHANGERS MARKET VALUE, MARKET SHARE AND FORECAST TO 2030

8.1. Middle East Africa Brazed Plate Heat Exchangers Market Overview, 2022

8.2. Middle East Africa Brazed Plate Heat Exchangers Market Size and Share Outlook by Product, 2021-2030

8.3. Middle East Africa Brazed Plate Heat Exchangers Market Size and Share Outlook, By End User, 2021-2030

8.4. Middle East Africa Brazed Plate Heat Exchangers Market Size and Share Outlook, By Application, 2021-2030

8.5. Middle East Africa Brazed Plate Heat Exchangers Market Size and Share Outlook by Country, 2021-2030

8.5.1. Middle East

8.5.2. Africa

9. BRAZED PLATE HEAT EXCHANGERS MARKET STRUCTURE

9.1. Johnson Controls

9.2. Halma PLC.

9.3. Hochiki Corp.

9.4. Honeywell International Inc

9.5. Siemens AG

9.6. Robert Bosch GmbH

9.7. Firefly AB

10. APPENDIX

10.1. About Us

10.2. Sources

10.3. Research Methodology

10.4. Contact Information

Research Methodology

Our research methodology combines primary and secondary research techniques to ensure comprehensive market analysis.

Primary Research

We conduct extensive interviews with industry experts, key opinion leaders, and market participants to gather first-hand insights.

Secondary Research

Our team analyzes published reports, company websites, financial statements, and industry databases to validate our findings.

Data Analysis

We employ advanced analytical tools and statistical methods to process and interpret market data accurately.

Get Free Sample

At OG Analysis, we understand the importance of informed decision-making in today's dynamic business landscape. To help you experience the depth and quality of our market research reports, we offer complimentary samples tailored to your specific needs.

Start Now! Please fill the form below for your free sample.

Why Request a Free Sample?

Evaluate Our Expertise: Our reports are crafted by industry experts and seasoned analysts. Requesting a sample allows you to assess the depth of research and the caliber of insights we provide.

Tailored to Your Needs: Let us know your industry, market segment, or specific topic of interest. Our free samples are customized to ensure relevance to your business objectives.

Witness Actionable Insights: See firsthand how our reports go beyond data, offering actionable insights and strategic recommendations that can drive your business forward.

Embark on your journey towards strategic decision-making by requesting a free sample from OG Analysis. Experience the caliber of insights that can transform the way you approach your business challenges.

$4150- 30%

$6450- 40%

$8450- 50%

$2850- 20%

Didn’t find what you’re looking for? TALK TO OUR ANALYST TEAM

Need something within your budget? NO WORRIES! WE GOT YOU COVERED!