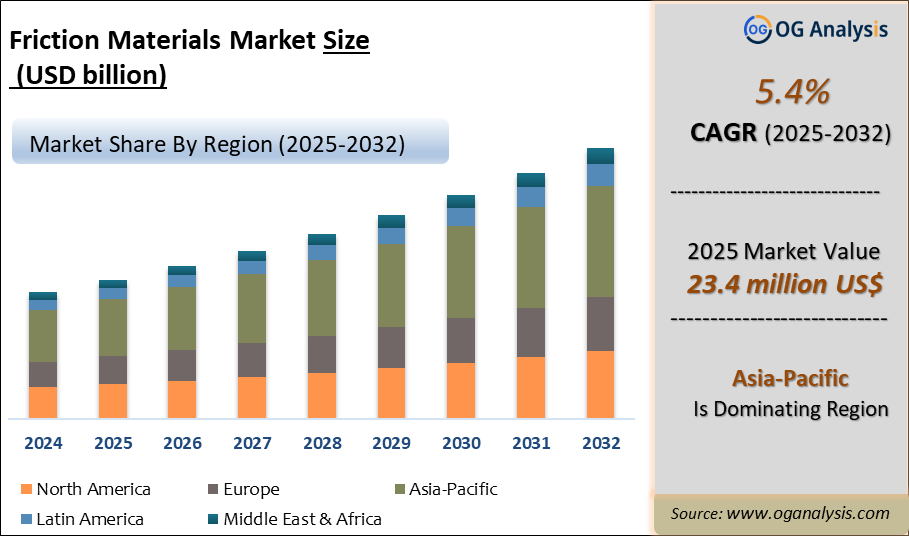

"The Global Friction Materials Market Size was valued at USD 22.4 billion in 2024 and is projected to reach USD 23.4 billion in 2025. Worldwide sales of Friction Materials are expected to grow at a significant CAGR of 5.4%, reaching USD 38.4 billion by the end of the forecast period in 2034."

The friction materials market is a critical component of various industries, including automotive, aerospace, and manufacturing, due to its role in braking and clutch systems. Friction materials are designed to convert kinetic energy into heat through friction, thus ensuring safe and efficient operation of machinery and vehicles. The market for these materials has evolved significantly over the years, driven by advancements in material science and increasing demand for high-performance products. Innovations in composites and ceramics have led to the development of friction materials with enhanced durability, reduced noise, and better thermal management. As industries strive for greater efficiency and safety, the friction materials market continues to grow, adapting to the specific needs of each sector.

In recent years, the friction materials market has been influenced by several factors, including the shift towards electric vehicles (EVs) and stringent environmental regulations. Electric vehicles, which require different friction materials compared to traditional internal combustion engine vehicles, have spurred research into new materials that can handle the unique demands of regenerative braking systems. Additionally, regulatory pressures to reduce vehicle emissions and improve fuel efficiency have led manufacturers to develop friction materials that are not only more effective but also eco-friendly. As a result, the market is witnessing a transition towards sustainable practices and innovative technologies, shaping the future landscape of friction materials.

Trade Intelligence for friction materials market

| Global Friction material and articles Trade, Imports, USD million, 2020-24 | |||||

|

| 2020 | 2021 | 2022 | 2023 | 2024 |

| World | 44.9 | 45.3 | 40.2 | 41.9 | 52.1 |

| Mexico | 6.17 | 4.94 | 2.83 | 5.49 | 9.58 |

| Viet Nam | 1.30 | 1.37 | 1.88 | 1.88 | 5.59 |

| Pakistan | 1.49 | 2.12 | 2.07 | 2.29 | 3.93 |

| South Africa | 1.20 | 1.27 | 1.93 | 2.14 | 3.69 |

| Indonesia | 4.09 | 3.85 | 1.92 | 2.24 | 2.09 |

| Source: OGAnalysis, International Trade Centre (ITC) | |||||

- Mexico, Viet Nam, Pakistan, South Africa and Indonesia are the top five countries importing 47.7% of global Friction material and articles in 2024

- Global Friction material and articles Imports increased by 15.9% between 2020 and 2024

- Mexico accounts for 18.4% of global Friction material and articles trade in 2024

- Viet Nam accounts for 10.7% of global Friction material and articles trade in 2024

- Pakistan accounts for 7.5% of global Friction material and articles trade in 2024

| Global Friction material and articles Export Prices, USD/Ton, 2020-24 |

|

|

| Source: OGAnalysis |

Latest Trends

One of the most prominent trends in the friction materials market is the increasing adoption of advanced composite materials. These composites, which often include fibers such as aramid or carbon, offer superior performance characteristics compared to traditional materials. They provide enhanced thermal stability, reduced wear rates, and improved noise and vibration damping. This trend is particularly evident in the automotive sector, where manufacturers are seeking materials that can deliver high performance while minimizing environmental impact. The shift towards composites is also driven by consumer demand for quieter and more comfortable driving experiences, highlighting the evolving expectations of the market.

Another significant trend is the growing focus on sustainability and the development of eco-friendly friction materials. With heightened awareness of environmental issues, manufacturers are investing in research to create materials that reduce harmful emissions and are recyclable. Biodegradable friction materials and those made from renewable resources are gaining traction as companies strive to meet regulatory standards and consumer expectations for greener products. This trend reflects a broader movement within the industry towards reducing the environmental footprint of friction materials while maintaining high performance standards.

The integration of smart technologies in friction materials is also on the rise. This trend includes the development of materials with embedded sensors that can monitor performance in real-time. Such advancements allow for predictive maintenance, improved safety, and enhanced durability by providing valuable data on wear patterns and operational conditions. The adoption of smart technologies is transforming how friction materials are used and managed, offering significant benefits in terms of efficiency and reliability. As the industry continues to innovate, the incorporation of these technologies is expected to play a crucial role in shaping the future of friction materials.

Drivers

The friction materials market is being driven by several key factors, including the robust growth of the automotive industry and increasing safety regulations. The automotive sector, which is the largest consumer of friction materials, continues to expand globally, particularly in emerging markets. This growth is fueled by rising vehicle production and sales, which in turn drives demand for high-quality friction materials. Additionally, stringent safety regulations and standards require manufacturers to use advanced friction materials that ensure effective braking and stability, further propelling market growth. The push for enhanced vehicle safety and performance is a significant driver behind the continuous innovation and development in the friction materials sector.

Technological advancements in materials science are another major driver of the friction materials market. Innovations such as the development of high-performance composites and ceramics have enabled the creation of friction materials with improved durability, thermal resistance, and noise reduction. These advancements are particularly important in high-demand applications like racing and heavy-duty machinery, where performance and reliability are critical. The ongoing research and development in this area are leading to the introduction of new materials that meet the evolving needs of various industries, thereby driving market expansion.

Furthermore, the shift towards electric vehicles (EVs) and hybrid vehicles is a significant driver of change in the friction materials market. As the automotive industry transitions towards more sustainable transportation solutions, there is an increasing demand for friction materials that are compatible with EV braking systems. These systems often require materials that can handle regenerative braking and provide consistent performance under different operating conditions. The growth of the EV market is prompting manufacturers to innovate and adapt their product offerings to meet the specific requirements of these new vehicle types, driving overall market growth.

Market Challenges

Despite the positive growth trajectory, the friction materials market faces several challenges that could impact its development. One of the primary challenges is the increasing cost of raw materials, which can affect the pricing and profitability of friction materials. Fluctuations in the prices of key ingredients like metals and composites can lead to higher production costs, putting pressure on manufacturers to balance cost and performance. Additionally, the industry must navigate complex regulatory requirements related to environmental impact and safety, which can lead to increased compliance costs and operational hurdles. Addressing these challenges requires ongoing innovation and strategic planning to ensure that the market continues to grow sustainably while meeting the demands of both consumers and regulators.

Market Players

1. ABS FRICTION CORP.

2. ANAND Group

3. Carlisle Brake & Friction (CBF)

4. European Friction Industries Ltd

5. GMP Friction Products

6. Hindustan Composites Ltd.

7. ITT INC.

8. MIBA AG

9. Nisshinbo Holdings Inc.

Report Scope

| Parameter | friction materials market scope Detail |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2026-2032 |

| Market Size-Units | USD billion |

| Market Splits Covered | By Type, By Material, By Application, By End-User |

| Countries Covered | North America (USA, Canada, Mexico) |

| Analysis Covered | Latest Trends, Driving Factors, Challenges, Trade Analysis, Price Analysis, Supply-Chain Analysis, Competitive Landscape, Company Strategies |

| Customization | 10% free customization (up to 10 analyst hours) to modify segments, geographies, and companies analyzed |

| Post-Sale Support | 4 analyst hours, available up to 4 weeks |

| Delivery Format | The Latest Updated PDF and Excel Data file |

Market Segmentation

- By Type

- Discs

- Pads

- Blocks

- Linings

- Other Types

- By Material

- Ceramic

- Asbestos

- Semi-metallic

- Sintered Metals

- Aramid Fibers

- Other Materials

- By Application

- Clutch and Brake Systems

- Gear Tooth Systems

- Other Applications

- By End Use

- Automotive

- Railway

- Construction

- Aerospace and Marine

- Others

- By Geography

- North America (USA, Canada, Mexico)

- Europe (Germany, UK, France, Spain, Italy, Rest of Europe)

- Asia-Pacific (China, India, Japan, Australia, Rest of APAC)

- The Middle East and Africa (Middle East, Africa)

- South and Central America (Brazil, Argentina, Rest of SCA)

Recent Developments

- Brembo and SGL’s joint venture expanded production capacity for carbon-ceramic brake discs across European plants to meet growing demand in high-performance vehicles.

- Beijing Bei Mo Gao Ke announced plans for a partial shareholder stake sale, signaling internal restructuring and capital optimization.

- ICER Brakes highlighted strong sustainability achievements, including a significant reduction in CO₂ emissions and the use of recycled content in copper-free brake pads.

- Akebono broadened its aftermarket portfolio by adding new ProACT, EURO, and Severe Duty ceramic friction products, covering millions of additional vehicle models.

- ITT partnered with Arvedi to incorporate carbon-neutral steel into brake components, supporting global carbon-reduction targets.

- Tenneco unveiled a new low-emission brake technology that combines advanced friction formulations with coated discs to comply with upcoming emission regulations.

- Carboleg GmbH advanced innovation with a patent filing for friction materials integrating thermally stable minerals to improve environmental performance.

Get Free Sample

At OG Analysis, we understand the importance of informed decision-making in today's dynamic business landscape. To help you experience the depth and quality of our market research reports, we offer complimentary samples tailored to your specific needs.

Start Now! Please fill the form below for your free sample.

Why Request a Free Sample?

Evaluate Our Expertise: Our reports are crafted by industry experts and seasoned analysts. Requesting a sample allows you to assess the depth of research and the caliber of insights we provide.

Tailored to Your Needs: Let us know your industry, market segment, or specific topic of interest. Our free samples are customized to ensure relevance to your business objectives.

Witness Actionable Insights: See firsthand how our reports go beyond data, offering actionable insights and strategic recommendations that can drive your business forward.

Embark on your journey towards strategic decision-making by requesting a free sample from OG Analysis. Experience the caliber of insights that can transform the way you approach your business challenges.

FAQ's

The Global Friction Materials Market is estimated to generate USD 22.4 billion in revenue in 2024.

The Global Friction Materials Market is expected to grow at a Compound Annual Growth Rate (CAGR) of 5.4% during the forecast period from 2025 to 2032.

The Friction Materials Market is estimated to reach USD 34.1 billion by 2032.

$3950- 30%

$6450- 40%

$8450- 50%

$2850- 20%

Didn’t find what you’re looking for? TALK TO OUR ANALYST TEAM

Need something within your budget? NO WORRIES! WE GOT YOU COVERED!