Forging the Future: Inside the Global Titanium Mill Products Market

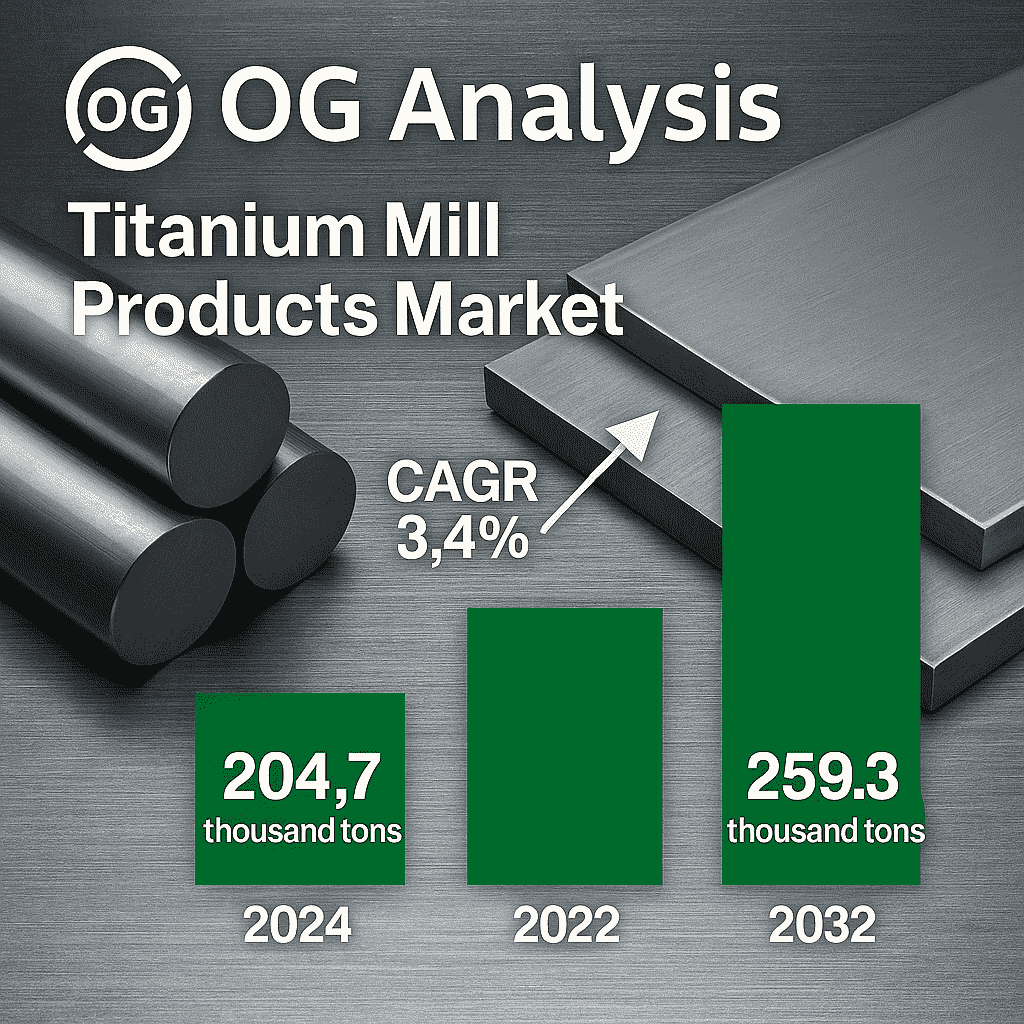

The Titanium Mill Products Market is steadily advancing, estimated at 197.8 thousand tons in 2023 and projected to grow from 204.7 thousand tons in 2024 to 259.3 thousand tons by 2032, expanding at a CAGR of 3.4%. Known for its exceptional strength-to-weight ratio and corrosion resistance, titanium continues to play a critical role across aerospace, industrial, and emerging applications. Let’s break down the evolving landscape through 7 engaging questions.

1. Why is titanium still considered the "metal of the future"?

Titanium’s exceptional combination of strength, corrosion resistance, and lightweight characteristics makes it indispensable in aerospace, defense, marine, medical, and energy sectors. With global focus shifting toward durability, sustainability, and high performance, titanium's strategic importance is only deepening, especially in extreme operating environments.

2. Which end-use industries are driving the highest demand for titanium mill products?

-

Aerospace remains the largest consumer, with titanium critical for airframes, jet engines, and landing gears.

-

Industrial applications such as chemical processing plants, desalination facilities, and offshore structures are expanding titanium’s role due to its superior resistance to corrosion.

-

Emerging sectors, including medical implants and EVs, are creating fresh opportunities for titanium growth outside traditional segments.

3. How are product types like sheets, billets, and pipes evolving in the market?

-

Sheets & Plates: Growing demand in the aerospace industry for skin panels and structural components.

-

Billets & Bars: Used heavily for forged aerospace components and precision medical devices.

-

Tubes & Pipes: Gaining popularity in energy and chemical industries due to resistance to extreme temperatures and aggressive chemicals.

Click Here for the Full Market Report:

4. What new opportunities are opening up for titanium suppliers?

-

3D Printing and Additive Manufacturing: Titanium powder and billets are becoming critical feedstock for aerospace and medical 3D printing.

-

Medical Applications: Orthopedic implants and dental prosthetics are increasingly relying on titanium’s biocompatibility.

-

Green Energy: Growth in offshore wind energy and hydrogen fuel systems is opening non-traditional markets for titanium mill products.

5. How are regional dynamics shifting titanium mill products demand?

-

North America: Driven by aerospace leadership (Boeing, Lockheed Martin) and rising defense budgets.

-

Europe: Strong demand for titanium from Airbus and energy-transition initiatives.

-

Asia-Pacific: Fastest growth fueled by China’s expanding aerospace industry, Indian defense programs, and Japan's advanced industrial base.

-

Middle East and Africa: Increasing offshore oil & gas projects and desalination plants are boosting titanium needs.

-

South & Central America: Emerging market for industrial and mining applications.

6. Which major players are dominating the titanium mill products landscape?

Industry leaders like Titanium Metals Corporation (TIMET), Allegheny Technologies (ATI), VSMPO-AVISMA, and Baoji Titanium Industry Co. are pushing boundaries with expanded production capacities, investment in titanium powder technologies, and long-term supply agreements with aerospace giants.

7. What are the future trends to watch in the Titanium Mill Products Market?

-

Rising adoption of recycled titanium to reduce production costs and carbon footprint.

-

Increased focus on additive manufacturing for faster, more customized titanium part production.

-

Stronger ties between titanium producers and EV battery and lightweight chassis designers.

-

Innovation in titanium alloy development to optimize performance for new aerospace and defense platforms.

Click Here for the Full Market Report:

Market Segmentation Snapshot: Key Categories and Regional Insights:

By End-Use Industry

-

Aerospace

-

Industrial

-

Others

By Product Type

-

Sheets & Plates

-

Billets & Bars

-

Tubes & Pipes

-

Others

By Geography

-

North America (USA, Canada, Mexico)

-

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

-

Asia-Pacific (China, India, Japan, Australia, South Korea, Indonesia, Malaysia, Vietnam, Rest of APAC)

-

Middle East and Africa (Saudi Arabia, South Africa, UAE, Iran, Egypt, Rest of MEA)

-

South and Central America (Brazil, Argentina, Chile, Rest of SCA)

Key Companies Shaping the Market:

-

Titanium Metal Corp. (TIMET)

-

Allegheny Technologies Inc. (ATI)

-

RTI International Metals / Alcoa Corp.

-

VSMPO-AVISMA Corporation

-

Baoji Titanium Industry Co. Ltd. (Baoti Group)

-

Arconic

-

Nippon Steel Corporation

-

Kobe Steel

-

Osaka Titanium Technologies Co. Ltd.

-

Norsk Titanium

-

PCC Structurals (Precision Castparts Corp.)

-

Western Titanium

-

CITIC Titanium

-

Midhani (Mishra Dhatu Nigam Limited)

-

ZIRCOT Products

-

TW Metals

Explore More Industry Insights:

Silicon Metal Market Outlook Report

Industrial Garnet Market Outlook report

Connect with us on:

Phone: +91 888 64 99099

Email: mailto:sales@oganalysis.com

Learn More about OG Analysis

OG Analysis, established in 2009 has 14+ years of experience and served 1800+ clients from 980+ companies operating in 54+ countries. OG Analysis is a leading provider of market research reports in Chemicals, Energy, Oil & Gas, Food & Beverage, Electronics & Semiconductors, Automotive, Telecommunication, Healthcare and Other industries.