The Global FEP Heat Shrink Medical Tubing Market: Precision, Performance, and the Future of Medical Innovation

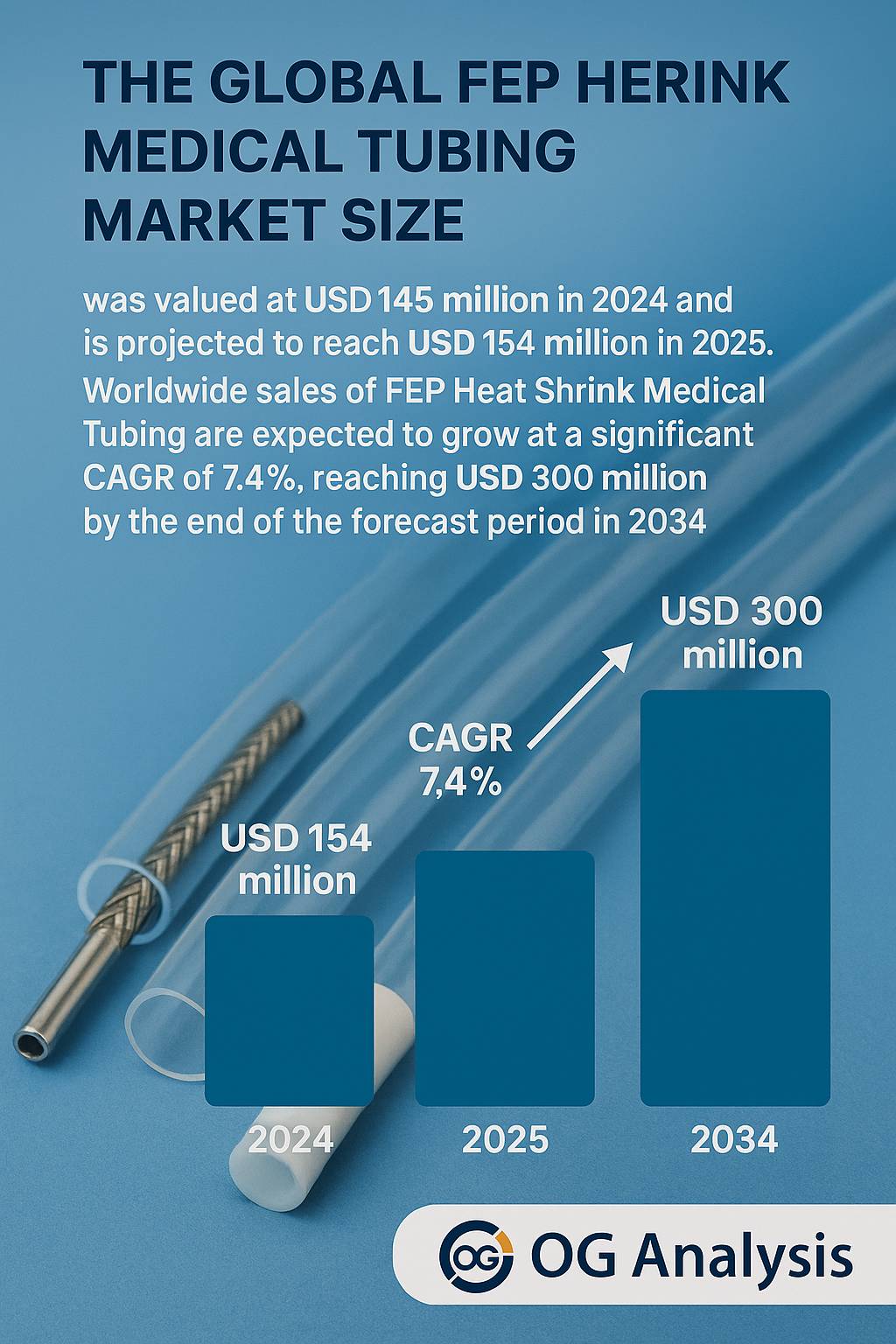

The global FEP Heat Shrink Medical Tubing Market is undergoing significant transformation, driven by the growing demand for advanced medical devices and precision-based healthcare solutions. Valued at USD 145 million in 2024, the market is projected to reach USD 154 million by 2025. Looking ahead, it is expected to nearly double, hitting USD 300 million by 2034 with a steady CAGR of 7.4%. FEP (fluorinated ethylene propylene) heat shrink tubing plays a vital role in medical device assembly, offering exceptional chemical resistance, biocompatibility, and transparency — all critical in today’s sophisticated healthcare systems.

This highly specialized tubing is primarily used in applications such as catheter-based drug delivery, surgical and vascular instruments, and electrical insulation of delicate medical electronics. Its ability to precisely conform to components under heat makes it an ideal choice for flexible joints, shaft reinforcement, and other tight-tolerance medical procedures. As regulatory pressures for safety and cleanliness grow, FEP’s non-stick, inert, and sterilizable properties provide a clear advantage over alternative materials.

7 Engaging Questions That Highlight the Evolution of the FEP Heat Shrink Medical Tubing Market:

1. Why is FEP heat shrink tubing gaining popularity in catheter and drug delivery devices?

FEP tubing’s precision fit, exceptional lubricity, and ability to maintain structural integrity during sterilization make it ideal for catheter-based drug delivery systems. It allows for minimally invasive procedures while ensuring biocompatibility and reduced patient risk.

2. What are the top innovation trends shaping the medical tubing landscape today?

Trends like miniaturization, multi-layer construction, and high-clarity extrusion are redefining performance benchmarks. FEP is especially suited for these advancements due to its consistent shrink ratios, superior chemical resistance, and compatibility with advanced surgical instruments.

3. How do shrink ratios like 1.3:1 and 1.6:1 impact medical device performance?

These shrink ratios define how tightly and uniformly the tubing can conform to components when heat is applied. The right ratio ensures better insulation, enhanced torque response, and improved device maneuverability — essential in intricate surgeries and diagnostics.

Click Here for the Full Market Report

4. Which applications are driving the strongest demand for FEP tubing?

Catheter manufacturing leads the pack, followed by its growing role in surgical tools, vascular instruments, and electrical insulation in neurostimulators and defibrillators. As more devices become wearable and implantable, demand will only accelerate.

5. What’s fueling the rise of FEP heat shrink tubing in emerging markets?

Countries in Asia-Pacific and Latin America are experiencing a healthcare infrastructure boom. With increasing investments in medical manufacturing, these regions are rapidly adopting high-quality materials like FEP to meet international compliance and export standards.

6. How are medical OEMs leveraging FEP tubing for next-gen devices?

OEMs are using FEP tubing to create thinner, more flexible, and durable devices that enhance patient comfort and clinician precision. The tubing’s clarity also enables visual inspection of underlying components — a critical advantage in quality control.

7. Who are the key global players redefining the medical tubing market?

Prominent players include Zeus Industrial Products, Junkosha Inc., TE Connectivity Ltd., Optinova, Parker-Hannifin, and Polyfluor Plastics. These companies are heavily investing in R&D to support demanding applications like microcatheters, balloon catheters, and electrophysiology devices.

Click Here for the Full Market Report

Segmentation Overview: Understanding Market Structure:

-

By Shrink Ratio: 1.3:1, 1.6:1

-

By Application:

-

Drug Delivery (Catheter)

-

Surgical & Vascular Instruments

-

Flexible Joints (Shafting)

-

Electrical Insulation

-

Other Applications

-

-

By Geography:

-

North America (USA, Canada, Mexico)

-

Europe (Germany, UK, France, Spain, Italy, Rest of Europe)

-

Asia-Pacific (China, India, Japan, Australia, Rest of APAC)

-

Middle East and Africa

-

South and Central America (Brazil, Argentina, Rest of SCA)

-

Key Players of the Market:

-

Adtech Polymer Engineering Ltd.

-

Aokeray Medical

-

Apt Advanced Polymer Tubing GmbH

-

Elringklinger Kunststofftechnik GmbH

-

Fluortek AB

-

Gremtek Sas

-

Holscot Fluoroplastics Ltd.

-

Junkosha Inc.

-

Medical Extrusion Technologies, Inc.

-

Optinova

-

Parker-Hannifin Corporation

-

Polyflon Technology Ltd.

-

Polyfluor Plastics BV

-

Shanghai Yanke Precision Extrusion Technology Co., Ltd.

-

Shenzhen Sunbow Insulation Materials

-

TE Connectivity Ltd.

-

Tef-Cap Industries Inc.

-

Teleflex Inc.

-

Udey Medflex Tubes

-

Zeus Industrial Products Inc.

Click Here for the Full Market Report

Explore More Industry Insights:

Global High Purity Methane Gas Market Outlook Report

Global Zinc Pyrithione Market Outlook Report

Connect with us on:

Phone: +91 888 64 99099

Email: mailto:sales@oganalysis.com

Learn More about OG Analysis

OG Analysis, established in 2009 has 14+ years of experience and served 1800+ clients from 980+ companies operating in 54+ countries. OG Analysis is a leading provider of market research reports in Chemicals, Energy, Oil & Gas, Food & Beverage, Electronics & Semiconductors, Automotive, Telecommunication, Healthcare and Other industries.